Cleaning

Cleaning and maintenance of structures which are continually subjected to corrosive elements and debris buildup is a key element in managing the overall performance of a waste water system. Lift stations, manholes, wet wells, vaults, tanks and treatment plant headworks all benefit from periodic cleaning to ensure the system functions at full efficiency. Hydro blasting and sand blasting services are used to tackle even the most resistant build-up and are used as a preparatory step should the structure require rehabilitation. Combination machines, industrial vacuum dry loaders and other essential equipment assist with debris disposal during the cleaning process.

Sanitary Sewer

Pipes are scoured with water propelled high pressure jets capable of producing from 2,000-4,000 psi to remove accumulated debris and return the pipe to its maximum flow capacity. A variety of specialized nozzles and cutters may also be used to remove hardened deposits and root intrusions. In situations where high flow hinders the efficiency of the cleaning operation, the pipe will be isolated using plugs and/or by-pass pumping.

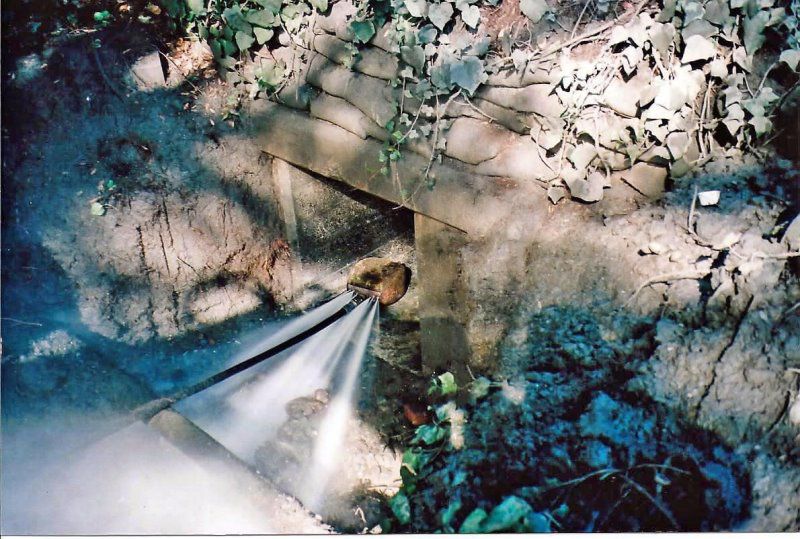

Storm Drains & Culverts

Clogged storm drain systems pose the threat of flooding during heavy rains causing costly repairs to the structures they were designed to protect. We specialize in the removal of accumulated debris that, if left in place, could result in flooding and hazardous conditions. From hydro-cleaning to bucket machines, MSI has the experience and equipment necessary to return the drainage system to its best possible condition

Wells

Horizontal edge drains range in size from one and a half to two inches in diameter. These wells utilize perforated pipe to dewater, relieving hydraulic forces in unstable locations. Over time the wells will become clogged with soil and roots and require cleaning. Hydro–jetting the pipe will cut root intrusions and remove mineral and soil build–up throughout the well.

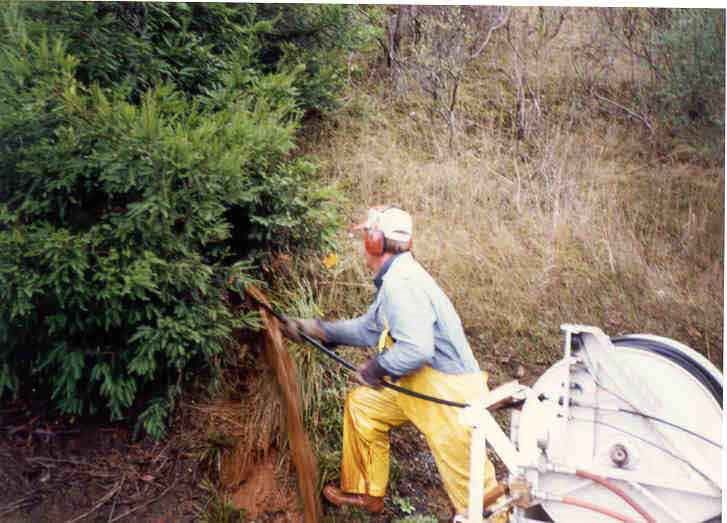

Manhole & Lift Station Cleaning

MSI cleaning units are equipped with hand-held water guns capable of generating a high pressure spray directly at the exposed surface to remove aggregated build-up. This process is used for standard maintenance purposes or in preparation for restoration of the structure.

Industrial Cleaning

Hydro Blasting:

High pressure pumps and nozzles are capable of producing between 4,000 and 10,000 psi of water force to strip and clear residue from interior and exterior surfaces. Steam can be incorporated into the cleaning process when necessary to achieve the desired results.

Wet Glass Blasting:

High-impact sand blasting is another method used to remove surface contaminants and is particularly useful when the water/sludge by-product of hydro blasting is restricted. When rehabilitation of the structure is necessary, the deteriorating surfaces will be sandblasted to remove loose debris creating a stable surface ready to accept the next step in the restoration process.

Concrete Cutting:

Flex lancing usually necessitates 10,000 psi water pressure. Tube bundle residue varies in thickness and density. Specialized rotating nozzle tips perform cleaning operations on these, sometimes totally restricted, tubes. Foot control valves are essential pieces of safety equipment for applications where the jetting operator is unable to see and communicate directly with the machine operator. This also applies to applications where a stainless steel semi flexible lance without a dump type trigger assembly is used.

Wet Abrasive Blasting

Requiring hand held equipment with pressures ranging from 4,000 to 10,000 psi, various abrasive materials are injected into the water flow through a Venturi nozzle. Very controllable results can be attained by this method. Water effectively retards the dust and reduces the heat (warping effect) which are major negative byproducts of conventional blasting methods. Abrasive materials range from sand to crushed walnut shells or almost any abrasive, free flowing material can be used depending upon the results required. A unique feature includes the ability to recover abrasive and allow reuse.

Tube Bundles:

Flex lancing usually necessitates 10,000 psi water pressure. Tube bundle residue varies in thickness and density. Specialized rotating nozzle tips perform cleaning operations on these, sometimes totally restricted, tubes. Foot control valves are essential pieces of safety equipment for applications where the jetting operator is unable to see and communicate directly with the machine operator. This also applies to applications where a stainless steel semi flexible lance without a dump type trigger assembly is used.

Communication Conduits:

Today’s infrastructure was installed with yesterday's technology. Vitrified clay tiles with no mortar joints are susceptible to root intrusion and sifting backfill. Jetting flushes the conduits, cuts roots and lubricates the passage for insertion of a pull rope or interduct casing. Our unique jump jet capability allows us to jet along side a cable pair already occupying a conduit.